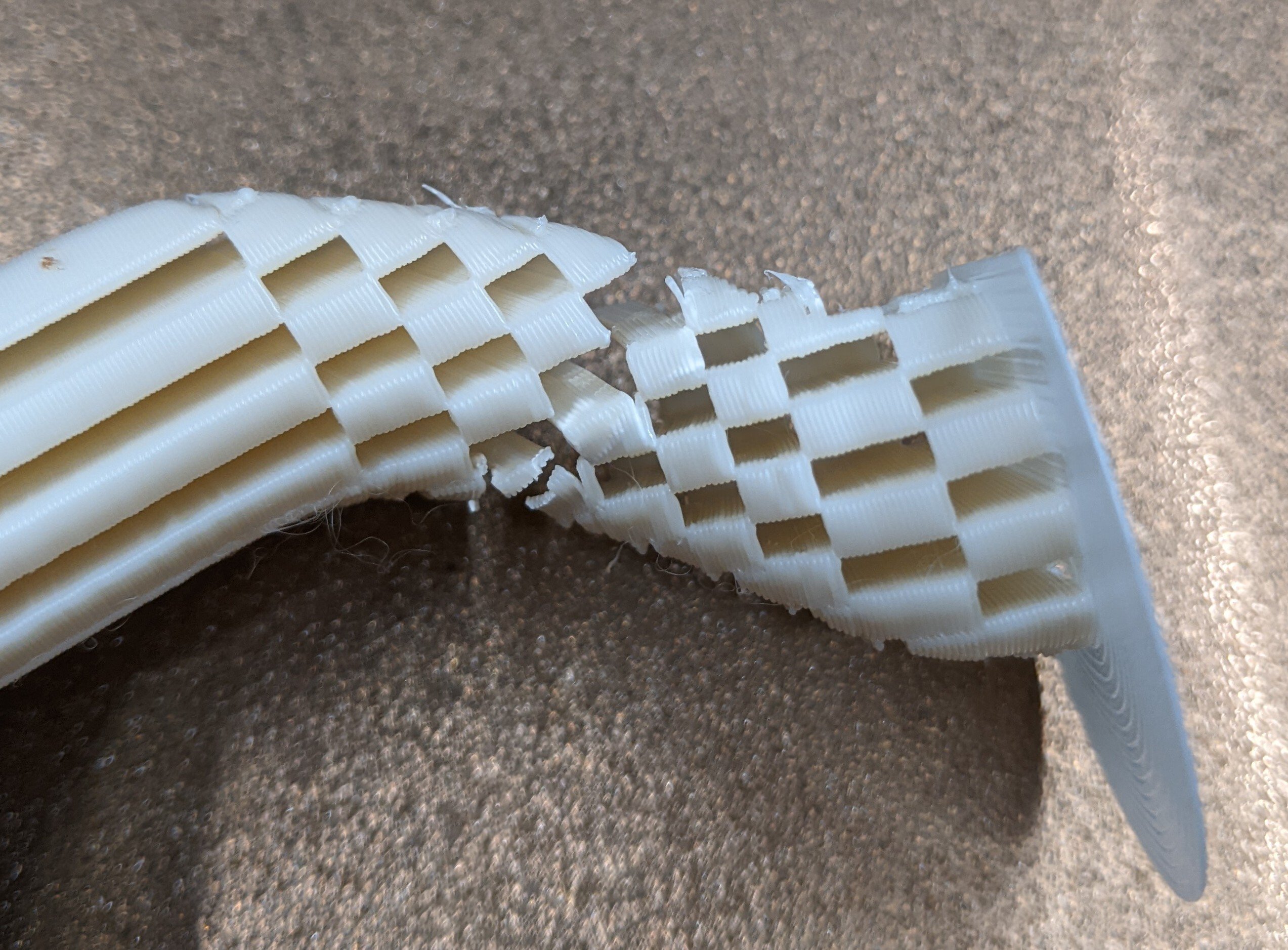

At least so far. The first go round had the nozzle crash into the tree support, resulting in a layer shift. The good news is that the print stayed very firmly stuck to the bed.

I’ve reset, lowered my extrusion multiplier a smidge, switched to a more traditional support pattern, and am going for it again. Wish me luck!

All the electronics inside are very much capable of combustion.

Your power supply inside the printer body for example can very much fail and burst into flames.

And tbh it’s not that uncommon for that to happen with 3d printers. They’re often made with very cheap parts and prone to cheap work on the inside bits.

Add on how much of a high wattage load they meed to handle for extended periods of time and yeah, sometimes the inner wiring bursts into flames and the whole thing goes up.

I always recommend keeping a cheap lil smoke alarm directly overhead any 3d printer, seriously. Those fuckers can very much spontaneously burst into flames lol

The electronics are housed in a (reasonably) sealed airspace below the print bed and have two fans blowing across them. Here’s a link to CAD/STLs/some pictures: https://vorondesign.com/voron2.4. If you want to poke around GitHub, you can do so here: https://github.com/VoronDesign/Voron-2. No printer is perfect, but Vorons are fairly well thought out and I didn’t skimp out on components when I was sourcing parts. All wiring inside the enclosure is either PTFE or silicone insulated.

Here’s what it looks like underneath:

Totally covered.

I do get where you are coming from with outlining all of the precautions you have taken, and I agree that the print is 99% likely to go just as fine as all your other ones, but there’s no amount of planning or prepping you can do that will change the fact that putting a pile of flammable articles over a massive source of thermal energy is indeed a fire hazard.

This is coming from someone with a very not ideal setup that does not have great fire safety precautions. (It’s inside a wooden hutch with a curtain draped over it for heat retention… 😬) I understand that my setup is dangerous, and I accept those risks. You aren’t making yourself any safer in denying your own.

EVGA had PSUs that blew up. Samsung is still too afraid to put ultra fast charging in their phones because they were blowing up. AMD GPUs were starting fires like 10 years ago. Just because you bought nice parts, doesn’t mean you aren’t dumping a ton of power through very delicate and fragile components that at any second could decide to kill themselves and everyone around them.

Not trying to say you shouldn’t do this because it’s your setup and you know it better than people online, just that you should keep in consideration when making these decisions that none of the things you’ve explained will matter if a large capacitor goes pop, and if it’s under a pile of sweaters you’ll probably have a much bigger problem to deal with than you would have otherwise.

Ultimately, if the printer is going to go up in flames the source of those flames won’t originate at the cloth draped over the acrylic enclosure. The chamber barely cracked 60 °C, which is well below what smaller Vorons, especially V0s, will hit with only acrylic panels. Yay lots of surface area I guess.

It will be very interesting to see how everyone reacts (or doesn’t) to some “better looking” insulation. The sources of ignition won’t be any different, but I bet that people will be much more comfortable looking at insulated ACM panels that were built for purpose.

We aren’t saying that the clothes are going to cause the printer to catch fire.

If the printer did catch fire, those clothes are going to make it a million times worse. You’re correct when you say most of the printer is not flammable. If your printer caught fire normally, it might run out of fuel before the fire was able to spread anywhere else in your house. If there’s the tiniest flame now, those sweaters are going to create a ball of inferno. It’s the exact same reason why every space heater says not to dry clothes on them, 99% of the time nothing bad will happen but if something bad does happen that 1% you don’t want to literally add fuel to the fire.

People are going to be fine with the “better looking” insulation because as you said insulation is made for this purpose and is usually fire retardant.

It’s a dangerous setup man. No if ands or buts about it. I’ll say the same thing again, I’m not here to tell you to change anything because mine is dangerous too, but if you’re going to do stuff like that it’s really important that you understand what you’re doing (and why it’s dangerous). I get that people online tend to try to find issues with everything, but sometimes people aren’t just complaining because something “looks bad”, and in communities like this it pays to look into stuff before assuming you know better than everyone trying to tell you the same thing.

Well, you’ve just decommissioned my printer until I’ve changed the smoke detectors batteries