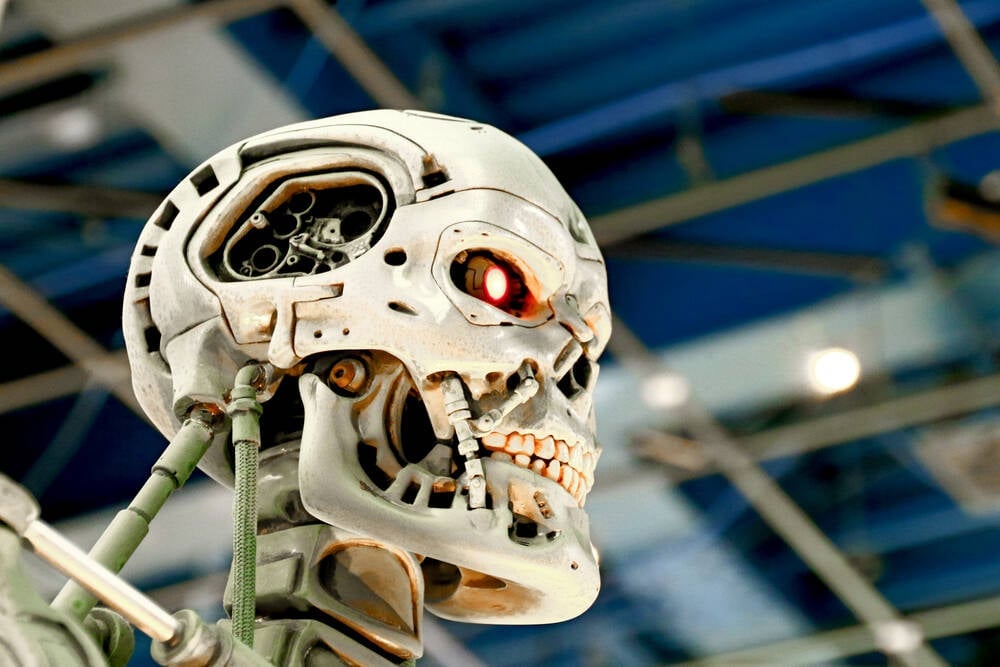

Robot mistakes man for box of peppers, kills him — Malfunctioning sensor system blamed for technician’s death at Korean food plant::Malfunctioning sensor system blamed for technician’s death at Korean food plant

Sounds like plant management needs to enforce lock-out tag-out procedure. That’s rule 1 of working on heavy machinery, no matter how safe you think it is.

The tech probably had work requirements that made it impossible to actually have time to do safety procedures. Management is always a part of the problem in these situations.

I haven’t been in a plant where management tells everyone to go crazy and ignore safety because 1. they aren’t monsters and 2. lawsuits. They’re financially motivated to do the right thing. When I saw the article, my first thought was this person disabled mandatory lockouts because it’s convenient.

I’m not insinuating that. I’m thinking that it’s more like management putting on a face to say “do all of the safety procedures. You have 30 minutes to fix this issue” when safety procedures take 30 minutes by itself.

Have you been in a South Korean plant? They famously have terrible working conditions, though they’re starting to fight back against that.

He was a technician from the robot manufacturer, so it’s on them for not having a proper procedure for maintaining sensors while the motors are disabled. I can’t imagine working on an industrial robot while the motors are powered… That’s completely reckless.

It’s reckless, but unless someone with authority is being a pain in the arse about safety, you don’t have a safe work culture that encourages that kind of behaviour. This is yet another example of the holes in the Swiss cheese lining up.

Did you read the article? The guy was diagnosing a sensor issue, can’t LOTO, you would have no power to diagnose the issue with.

You could disable the motors. You can read out sensors without the arm moving. And if the arm needs to move, do it from a distance (cable connected or wireless).

A human shouldn’t be anywhere near moving robotic arms, ever.

The guy worked for the robot manufacturer, according to the article! You’d think would have been much more aware of the robot’s reach, and the safety procedures. Plus, I’m pretty sure you can step through the robot programming slowly. I’ve seen our programmers do it. Please don’t tell me he was in the cell standing next to the crate or whatever, with that thing running full production speed.

To be clear, you oft times can’t easily debug live code on a piece of machinery. Unless it was specifically designed to accommodate, 99/100 times it’ll be nigh impossible without digging in a soldering things to other things. And that is usually not something done on a factory floor.

You’re not wrong, but there is also a reason for each of those things to not be possible in lots of scenarios. The article made it sound like it was commissioning test, you have to do functional tests on the entire system, not individual parts at that point.

The machine may not have been able to be cable connected or wireless or maybe the employee cut corners too, people seem to forget this part too.

You shouldn’t, but there is plenty of usecases where someone needs to unfortunately, that’s just the reality of the world.

It’s not the reality of the world, it’s cutting corners. Most likely management either not providing the equipment or putting so much time pressure on employees that they have to rush.

Absolutely no one is testing robotic arms while standing next to them. They would either be moronic or are forced to (which should be illegal). Especially with the AI being switched on instead of using manual control in that moment.

But work safety standards are shit in a lot of countries.

It’s not the reality of the world, it’s cutting corners. Most likely management either not providing the equipment or putting so much time pressure on employees that they have to rush.

Sounds like real world to me. Correct? No. Real? Yes.

Yes cutting corners is the reality of the world, employees do it, management does it, public does it, private does it, union does it, everyone does.

And yes it does happen and is a necessity in plenty of cases. There is ways to make it safer, but everything has an inherent danger and nothing is ever 100% safe or have no risk. That’s just not possible, another reality of the world.

If the issue was with the AI, yeah you would it to be on AI instead of manual.

A sensor issue on any machine, intelligent it not, is not justification to forgo a lock out, tag out of that machine.

It is like a shredder that only activates if something is in the hopper. If the sensor can only be accessed in the hopper, the shredder should not be operational when fixing the sensor.

There are many ways to do this safely. All robotic arms come with a disable key that powers off the axis motors, latches all the brakes, but leaves the sensors and end of arm tooling powered up to troubleshoot. Troubleshooting can also be done via PC and watching inputs/ outputs on the program.

That’s just not true, more modern machines may have those safety features, but they aren’t on every thing.

Which again falls on the company not following proper safety, which was the point. This was a foreseeable problem, and the fact that the arm was “looking” for and able to reach for a box of “peppers”, means it was not in the right state to trouble shoot. If the device has no safety mechanisms that would allow safe maintenance then the machine must be replaced. But they don’t have good standards in a lot of countries.

Even in Canada and US legacy systems don’t have to be replaced with more modern ones, only when they are no longer usable and have to replaced do they need to meet new codes and standards.

Just because a new code comes out doesn’t mean every machine is suddenly obsolete…

There are only a few manufacturers of robotic arms, and have this feature as it is required by law in many countries. This was a new installation and I’ll be happy to bet all sorts of money that it had it installed and wasn’t used.

What model of arm was being used here? Because the article makes no mention and actually talks about a robot, so that sounds like something else than this “arm” you speak of.

There are more to robots than just “robotic arms”…. And to claim that those all have the features of a very specific model is quite frankly asinine.

In any industrial context, a “robot” is short for robotic arm. Those things you see in footage of automotive factories.

They also don’t have any kind of AI. It’s just a regular (if specialized) computer in control.

That’s just unequivocally wrong a robot is any complicated machine that can do a task. A palletizer is a type of robot and has zero arms.

And yeah they can have Ai or not, don’t change well established industry definitions to fit your narrative….

The article I had read about it said it was being looked at for sensor issues in the first place. It was extra dumb to be looking at that live robot.

Why is it programmed to kill boxes of peppers

For the same reason that someone decided that it would be a good idea to have machines be able to generate energy from organic material….

Yeah, let’s build robots that can feed on humans to recharge their batteries, no way that’d be a problem.

Horizon Zero Dawn showed us that this doesn’t have any potential to be problematic…

And live on a world where you can defy physics mods “bullet time”

ULTRAKILL be like:

It’s 로봇 크러쉬 [Robot Crusher] brand. They advertise this cooking process and must therefore kill boxes of peppers with prejudice and treat their structure with total disrespect.

© 2023 로봇 크러쉬™

I don’t see where that was stated that it was programmed to do that. Not sure if dad joke or just really stupid person.

Wtf is this fear mongering? I’m totally for luddism but this is something else. Not the first time a machine kills a person, and will not be the last. Put panic stop buttons on any machine that can potentially harm a human, and nowadays you can add a range of sensors that can help identify a living thing from a box of vegetables. This is entirely the fault of designers.

Btw i refuse to read the article if the post keeps this title and picture.

“Man Dies in Industrial Accident” is a lame headline. 🙄

it had a sensor for it, it malfunctioned, now why it wasn’t turned off while the tech was in there is another story. If they were testing it, they should have been a safe distance away or had it mostly powered off. This is just unsafe work environment.

My first question when I read the article was why didn’t they lock out/tag out the machine before getting in it?

A thread on a different article about the same thing had someone demanding a change in law to make robots safer and stop this happening again because 48 people were killed by robots in the USA…since 1992.

Yes, there’s a lot to take in with that. Yes, some people are idiots.

deleted by creator

deleted by creator

Wouldn’t you like to be a pepper too?

Wait until you hear how crazy dangerous this thing called the cotton gin is.

So I never understood the importance of the cotton gin until I grew some cotton for giggles.

Y’all ever tried to get those seeds out?! There’s 4-8 per boll and they are enmeshed. Just cleaning a couple of puffs is a tough chore. And waste as little as possible. Now do 40 acres. The bales around here are about the size of a short tractor trailer box.

Also, try picking cotton some time. Puts a whole new spin on slavery. By harvest time those leaves turn into pointy, hardened razor blades. I barely reached in and one slide up the side of my finger about 1/2". Took 2-weeks to heal since I apparently got a fat inoculation of bacteria.

Now do it fast, bent over, from pre-dawn to just past dusk. And get whipped if you don’t hustle. Slave’s hands had to be lumps of unfeeling callous.

Oh, and the part school didn’t teach about the cotton gin; It made cotton vastly more profitable. Guess where I’m going with this.

And to lighten the mood, have some racist ass field trip.

To end the thought, it made slavery worse since they were able to process the picked cotton faster.

Here is an alternative Piped link(s):

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I’m open-source; check me out at GitHub.

Eli Whitney has entered the chat

DEATH TO ABOMINABLE INTELLIGENCE!

Destroy the Heretek whomst wishes them upon us!

“Mistakes”?

Was it ever designed to attempt to tell the difference? Aren’t most packing “robots” just machines a basic set of sequences with maybe a sensor or two for the most egregious problems, like “there’s something here, do thing” vs “nothing here, don’t begin sequence”

Malfunctioning sensor system blamed for technician’s death at Korean food plant.

New FNAF lore?

now we know the bite of 87 was spicy, how does this tie in with everything else?

Gah dammit, and that movie was actually pretty decent too. Cereal Killer came through Thir13en Ghosts style.

C’mon bud, tag your spoilers lol

I meant he acted well in this film like he did in 13Ghosts, and well,…in Hackers as Cereal Killer

“We did not know back then but that was how it started” dark-synth music intensifies

Seriously, I’m sorry for his family and friends, hope the company will bleed for this

Add them to the list on Wikipedia

Wow. Robert Williams’ death was a very interesting one legally. I wonder if Ford would have gotten away Scott free of they weren’t such a huge manufacturer in the area.

deleted

What I don’t understand is why the grip claw needed to be applying enough strength to crush a human torso and skull, or even be able to close far enough to cause damage to a person to do its job

deleted by creator