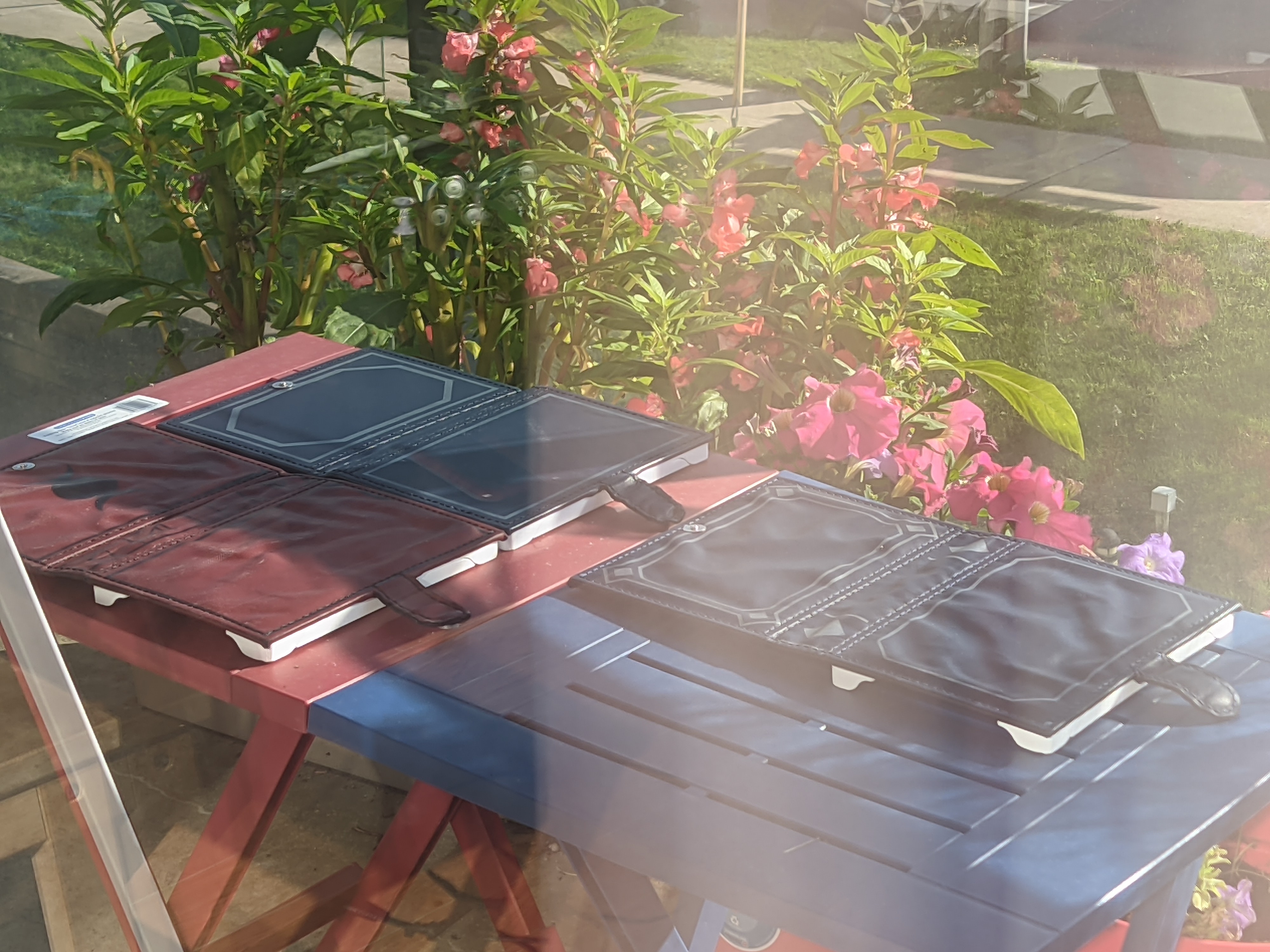

I made a 3d printable eReader case for my wife. Wanted to test what would happen if we water logged them and left them in the sun to dry.

Two of the cases are made from PLA while the other is made from PETG. They are all held together by thread and leather.

The test here is to see if moving from PLA to PETG was the right move since the last time I did this, the case turned into a banana.

My eventual plan once I’ve finished with my testing is to sell these cases and make their designs available for others to print.

Yes, PLA creeps ridiculously fast in hot conditions it is unsuitable for use in any environment over 35C tbh.

PETG is better but will still warp/fade over time if it’s exposed to the sun, and likely need replacing.

You need to be printing in ABS or ideally ASA if you want all-weather resistant cases. Which means now your printer needs an enclosure and ventilation…

I printed a sprinkler to stick on the end of my watering can out of PLA.

Its been outside in all weather, including direct sunlight, for three years now. And water runs through it almost every day for 8 months of the year. It’s a little faded, but that’s it.

IMO the things people say about PLA regarding exposure are vastly over stated.

It can survive fine when under no load. It probably fades color less than abs does actually. However When experiencing any kind of mechanical load - say, a tablet squeezing at the edges for a friction fit - it fails rapidly at elevated temperatures.

Yup, and any interior vehicle parts I’ve done that have any loads have yielded after any kind of sunny week or so.

Massively oversized parts can last a bit longer, but they just have very low creep temperatures.

That’s exactly how I know. Made some very nice interior car parts and experimented with the 3 plastics. PLA failed in a day, PETG made it a week before it sagged too much to be usable, but ABS is still going.

Yeah, I haven’t bitten the bullet and tried abs yet, mostly because I’m not ready to setup ventilation and better temp control.

Asa seems to be another option, but I’ve been having too much fun printing TPU parts to bother.

ahhh, TPU is addictive isn’t it. So squishy and flexy. I’ve even made gaskets out of it for an ATV- not good ones, because it fails to seal when too cold, but gaskets that still work nonetheless.

I don’t think your particular case would have any creep as it’s not mechanically leveraged in any real way.

If you were to print something like a cupholder for a stroller or bike where it’s holding something up with some weight while in the heat is where you would notice it especially with repeated impact. Most likely wouldn’t outright fail but under constant load you would notice it starting to bend a little. That said you can absolutely over engineer it to prevent that rather than switching materials which can be a huge pain depending on the printer.

I did my hydroponic tower in PETG but it honestly would’ve been ok in PLA since it’s just a static fixture. I’ve had a PLA badge on my car for 3 years in 110+ summers and similar to you I’ve only noticed fading on the raised white lettering.

I think it depends on the usage. If the size/shape doesn’t matter or is mated to metal, then PLA is more than fine in colder climates (i.e. not Texas), but as soon as the average temp of it’s operating environment is within the Glass Temp range then PLA isn’t good.

In your sprinkler’s case, the water is chilling it bellow glass temp when operating.

Would love to print in ABS, but every time I tried the parts always warped. PETG is nicer and has very rarely warped on me.

Yeah ABS is super finicky to print, a temp controlled enclosure is mandatory and you often need perfectly prepped full adhesive plates with large print brims. But it’s definitely the only true weather-tolerant plastic if you can get it to behave.

I think if I was ever at that point. I’d just use injection moulding

I just put a Amazon box over my printer, turned on brim, turned off part cooling and put glue stick over the print area! No warping from it! Did a lot of my voron parts like this before I built a proper enclosure!

It doesn’t have to be anything super complicated, it just needs to keep the heat in

An Amazon box probably works really well as a free enclosure, but I’d worry about the fire risk. The enclosure I made I put a fire detector in just to be safe, making it out of paper would make me very paranoid.

I did the same when printing my Voron parts in ASA. I didn’t use a glue stick and everything went pretty smoothly. I even put cardboard panels on my Voron while printing my magnetic panel clips, lol

ASA seems like an easier-to-print alternative to ABS, afaik only downsides are higher cost and fewer colours to choose from. Supposedly possible to print ASA without enclosure.

Yes, ASA is a more stable plastic overall. They both have issues with requiring ventilated enclosures tho.

Honestly this is a bit extreme in my opinion. I have been printing ABS for some years now. It is what i print in the most in fact. I am using a prusa MK3 (now S) without a enclosure. and it works just fine even rather large prints. Only thing to keep in mind is the fumes. In my case the printer is in a separate room which is well ventilated.

It depends heavily on your printing base. If you have a plate you can glue/put ABS slurry to, you’ll have enough adhesion that peeling is very unlikely to happen without an enclosure. If you’re trying to print directly onto a textured or PEI sheet without an enclosure, it’s gonna probably mess up.

In my case i do not use any sort of glue. I just print straight on the texured or PEI sheet. Never really hat issues. If it does not stick welll, I clean it with dishsoap. Seems to work best after a wile of use.

Yes, if you’re cleaning your build plate regularly you’ll probably not need the glue. I’ve had to do it once for a very weird part that was wide but with a small cross section though, and if the environment is cool it can and still will want to peel away from the plate.

Well, it’s been 2 minutes since you posted. Any updates?

:D

30 minutes in the test, I saw a cat.

That sounds like time well spent already.

Now if you are melting your 3d prints, make sure you flip it every 2.5 hours to get an even coating.

Finally, something 3-D printed for bibliophiles. You will make money with this as a niche, selling cases to people with older Kindles, for example. It’s very difficult to find a protective case for any of them that are more than five years old, IMHO. Bless your face!

Shhhh you’d ruin my whole plan.

Though you are absolutely correct. I’ve made a universal base with replaceable arms (since that’s what kept breaking on my wifes). All I need to do is fit the arms to the eReader and figgure out where the sleep magnet goes and bam, new eReader case.

Currently I’ve made cases for the Onyx Book Nova 3, Kobo Aura One, Kobo Nia, and Kobo Clara 2e. With plans to tackles anything I can easily get my hands on.

PETg is the top left?

Yup